The magnet manufacturing process typically involves several key steps to ensure performance and stability. It begins with raw material preparation, where rare earth metals or ferrite are mixed in precise proportions. The materials are then melted and milled into fine powders suitable for pressing.

Next, the powders are shaped and compacted in molds, followed by high-temperature sintering to densify the structure. Mechanical machining is performed to achieve the desired shape and dimensions. Surface treatments, such as nickel plating, zinc plating, or epoxy coating, are applied to improve corrosion resistance and durability. Finally, the magnets undergo magnetization and quality testing to ensure they meet the required magnetic properties and standards. Each stage is closely connected to guarantee magnets are ready for widespread use in electronics, automotive, medical, and other industries.

For more information, please contact us

1.Raw Material Preparation

Raw material preparation is the key step in magnet production. High-purity metals like neodymium, iron, boron, aluminum, nickel, and cobalt are precisely proportioned, melted, or blended to form the desired composition. Proper preparation ensures magnet strength, durability, and stability, while any impurity or misratio can compromise performance.

2.Melting

Melting is done in vacuum or inert furnaces to fuse rare earth metals, iron, and alloys into a homogeneous alloy while preventing oxidation. This ensures the right composition for strong, stable, and durable magnets.

3.Hydrogen Decrepitation

Hydrogen decrepitation breaks cast alloy ingots into coarse powders. The alloy absorbs hydrogen, expands, and cracks along grain boundaries, making it easier to mill into fine, uniform powders with less stress while preserving magnetic properties.

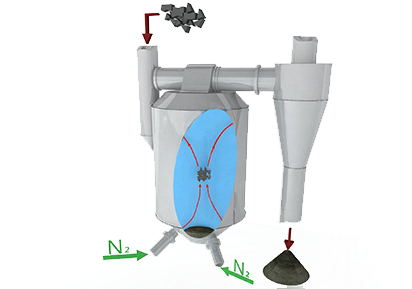

4.Jet Milling

Jet milling refines coarse powders from hydrogen decrepitation into ultrafine particles. High-pressure gas streams cause collisions, avoiding impurities and ensuring precise size control for uniform density, alignment, and optimal sintering.

5.Pressing

Pressing compacts fine magnetic powders into shape under high pressure. Using axial, transverse, or isostatic methods, with optional magnetic field alignment, it sets density and orientation, ensuring strength and stability for later sintering.

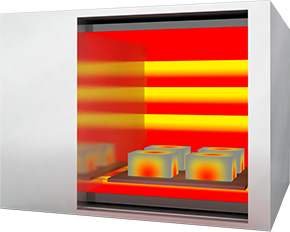

6.Sintering

Sintering heats pressed compacts in a controlled atmosphere, bonding particles by diffusion. This boosts density, strength, and magnetic alignment, enhancing coercivity, remanence, and stability. Precise control prevents grain growth or defects.

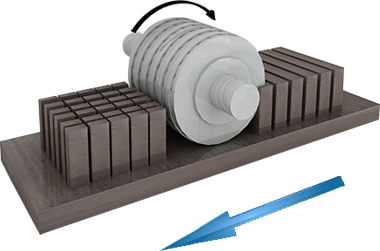

7.Machining

Machining shapes sintered magnets to precise dimensions using diamond or resin grinding tools to avoid cracks. It ensures accuracy, smooth finish, and consistency for use in motors, sensors, and electronics while preserving strength and magnetic properties.

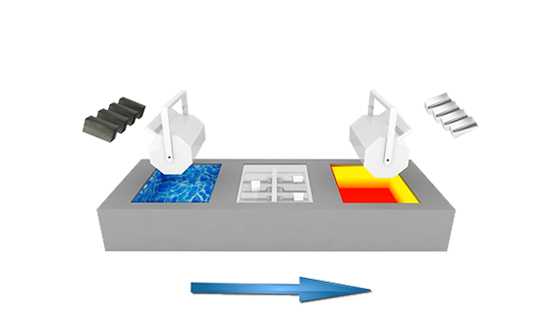

8.Surface Treatment

Surface treatment protects magnets from corrosion, wear, and damage. Coatings like nickel, zinc, or epoxy extend lifespan, enhance appearance, and ensure strength and integrity under harsh conditions.

9.Magnetizing

Magnetizing exposes finished magnets to a strong magnetic field to align domains, setting strength, polarity, and performance. Controlled magnetization ensures consistent, reliable operation in motors, sensors, and devices.

10.Delivery

Delivery packages and ships finished magnets with protective materials like foam, anti-static, or moisture-resistant layers to prevent damage, demagnetization, or corrosion, ensuring they arrive in optimal condition for industrial or electronic use.